1212S-2601 Curtis controller 1212S-2501

| Product name | dc motor controller |

| Model | 1212S-2601 |

| Part number | 17729710 |

| Used for | Electric pallet truck/electric stacker 1.5-2 ton |

| Product name | dc motor controller |

| Model | 1212S-2601 |

| Part number | 17729710 |

| Used for | Electric pallet truck/electric stacker 1.5-2 ton |

| Product name | dc motor controller |

| Model | 1212S-2601 |

| Part number | 17729710 |

| Used for | Electric pallet truck/electric stacker 1.5-2 ton |

OVERVIEW

The Curtis 1212S motor speed controller provides precise and smooth control of permanent

magnet drive motors for battery powered vehicles. This controller is designed for use in pallet truck

applications.

The 1212S controller is fully programmable by means of a Curtis programming device. Use of the

programmer offers diagnostic and test capability as well as configuration flexibility.

Curtis 1212S Electronic Motor Controller.

Like all Curtis motor controllers, the 1212S offers superior operator control of the vehicle’s motor

drive speed. Key features include:

Smooth and Secure Control

• Advanced speed regulation maintains precise speed over varied terrain, obstacles, curbs, and

ramps

• Linear cutback of current ensures smooth control, with no sudden loss of power during

undervoltage or overtemperature

• Proprietary algorithms help prevent gearbox wear while providing smooth starts and reversals

• The vehicle is brought to a complete stop before the electromagnetic brake is applied, ensuring

safe and secure stops under all conditions

• Charger inhibit input prevents driving while charger is attached

• Key Off Decel function ensures a smooth “brake to stop” when the key is turned off while

driving or when a fault occurs that requires the vehicle to stop

• Anti-Rollback/Roll-forward function provides smooth and safe vehicle control on hills and

ramps

• Internal main relay provides secure power-off

• Boost current gives a brief boost of current greatly improving transient loads such as starting

on a hill, crossing thresholds, etc.

Easy Installation and Setup

• Industry standard footprint, mounting centers, and wiring allows drop-in replacement of

other controllers

• 1212S controller is easily programmed with a Curtis programming device, or can be supplied

pre-programmed

• Accepts standard single-ended voltage/resistance throttles

• Throttle sense can be inverted for all throttle types

• Simplified troubleshooting and diagnostics

• Standard Molex Mini-Fit-Jr. terminals provide proven connections for the control wiring

• Bolt-on terminals provide robust connections for the high current wiring

Valuable Additional Features

• Automatic compensation for changes in motor condition to ensure optimum drive

performance at all times

• Multi-mode provides for two distinct and programmable control modes (indoor/outdoor)

• Emergency reverse with belly button switch input

• Lift Lockout input from Curtis 906 battery discharge indicator meter

• Output Lift Lockout signal, which can drive a pump contactor

• Pump SRO can be enabled to prevent pump startup when KSI first turned on

• Sleep function prevents the controller draining the battery when the vehicle is inactive

• Battery Discharge Indicator output

• Adjustable brake hold voltage reduces heating of the brake coil

• Reverse polarity protection

Robust Safety and Reliability

• High RF immunity prevents speed variation and shutdowns in noisy RF environments

• Controller power circuits and microprocessor software are continuously monitored for proper

operation

• On power-up, system automatically checks the throttle, brake, and associated wiring, and

disables drive if a fault is found

• Whenever the 1212S senses a loss of KSI or any fault that requires a stop, it smoothly

decelerates the vehicle to a stop

Meets or Complies with Relevant US and International regulations

• Electronics sealed to IP54

• Designed to meet EN12895:2000, EN13849-1(PL=B, Cat 2), and UL583.

Familiarity with your Curtis controller will help you install and operate it properly. We encourage

you to read this manual carefully. If you have questions, please contact the Curtis office nearest you.

CONNECTIONS: High Current

Four M4 bolt-on power terminals are provided for the high current connections: two for the motor

(M1, M2) and two for the battery (B–, B+). The recommended assembly torque for the M4 bolts

is 1.6±0.2 N.m.

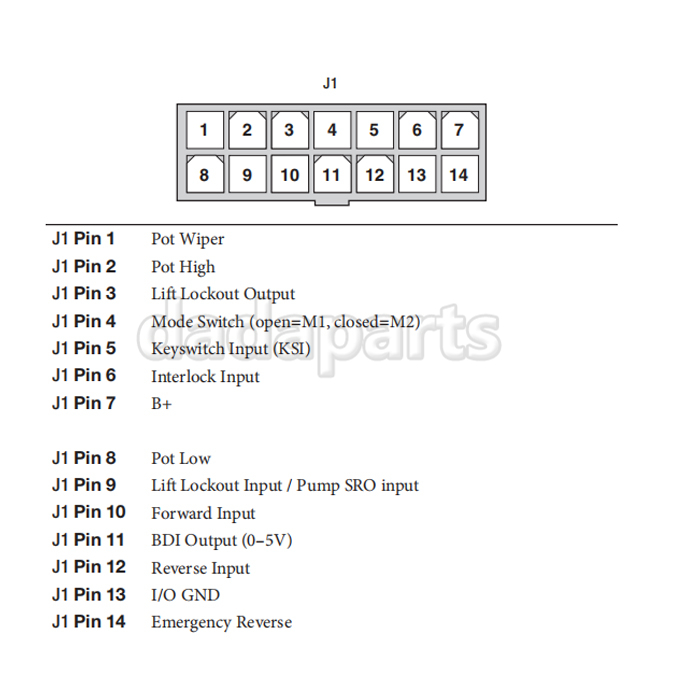

CONNECTIONS: Low Current

The low current logic control connections are provided by a 14-pin connector.

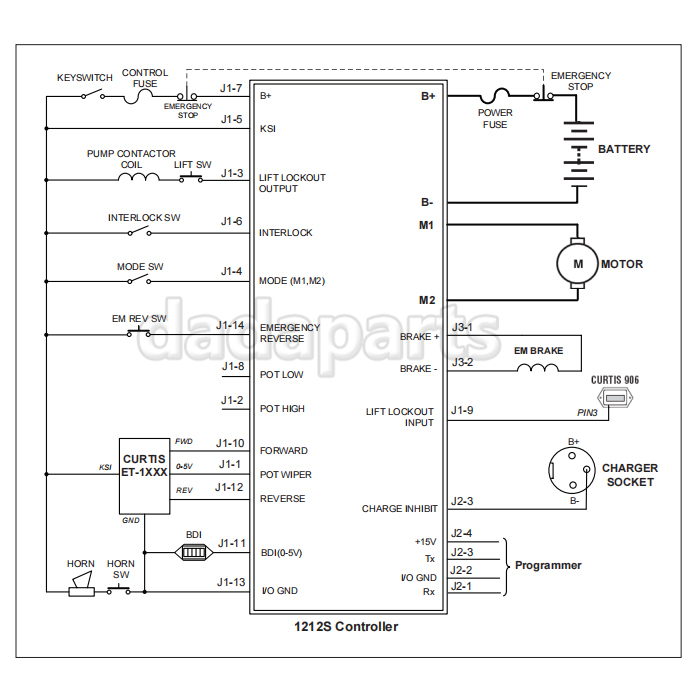

STANDARD INSTALLATION, 1212S-2601 1212S-2501

The wiring diagram presented in Figure 3 shows a typical installation for a pallet truck application.

This installation is shown with a Curtis electronic throttle.

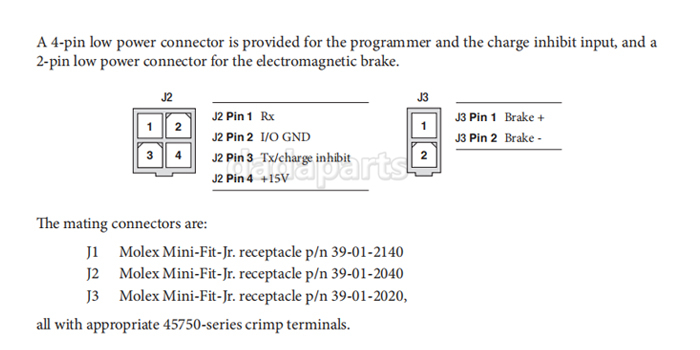

The J2 connector can be used interchangeably for the programmer or for the charge inhibit input.